What To Draw On A Handsaw

I often receive emails asking me nigh more mod saw makers and apart from a couple of modern makers more involved in finessing the finished tools they brand, I find myself unable to recommend near of the mass-fabricated saws for i simple reason – hard-signal teeth. Is it the hard-point teeth alone that fails the exam or something more? Induction hardened teeth mean that a perfectly good saw has to be discarded and at all-time might end up being recycled if we are lucky. Beyond even that there is some other problem and that is that most often these saws have teeth divers past shape for crosscutting wood and when they come to ripcutting along or with the wood grain they just don't cutting information technology.

I remember the transition coming into place when I didn't quite sympathise the first Spear and Jackson catalog entry almost 15, peradventure 20, years ago. Ii saws looked the same or similar, merely the kickoff saw said underneath, 'resharpenable', whereas the other said, "lasts 5 times longer than conventional saws". I passed over the comments at first, merely was left with a niggling feeling. Just what was going on hither? I had never seen anything said or phrased similar this before in a tool catalog and I and so realized what was happening. On the one hand there was a conventional saw that had steel hardness at a level that could be resharpened with a three-square saw file whilst on the other the steel was induction hardened electronically and that hardness meant that the sharpness would final five times longer but and then could not be resharpened by using traditional hand methods. The problem was this and then. What was being unsaid was that the new saw would last five times longer than the one-time saw when in fact information technology was the sharpness of the teeth that would last five times longer. This so led to the showtime disposable saws we see then highly prized today and yet in the construction trades this now makes sense fifty-fifty though it's still hard to reconcile making a throwaway saw.

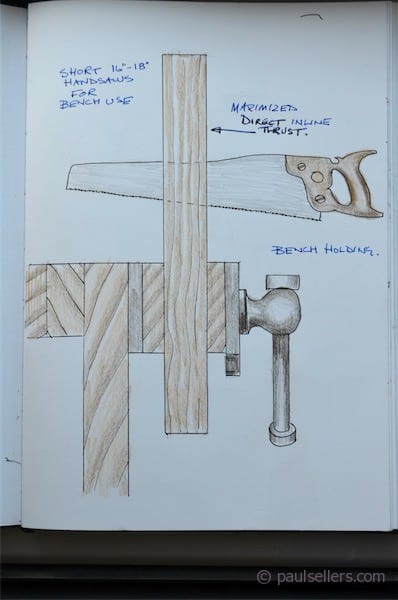

I think that what prompted these thoughts came as a result of my traveling from state to country. In my demo'south I have been working with a 16" Disston handsaw I bought on eBay for £10 ($15 usd). When people see its effectiveness they seem quite amazed. I rip and crosscut with the aforementioned saw too and so they brainstorm request questions. The saw is short and so that makes the saw somewhat unusual, only I similar its shortness for a couple of reasons. Ane, information technology's compact length makes information technology ideal for traveling with and, two, information technology'southward shortened punchiness gives the most inline directness that penetrates right at the heel of the saw. Every bit an at-the-bench saw, where wood is anchored differently than say on saw horses, the presentation of the saw to the wood is more than perpendicular and then has a directness other saws might not have.

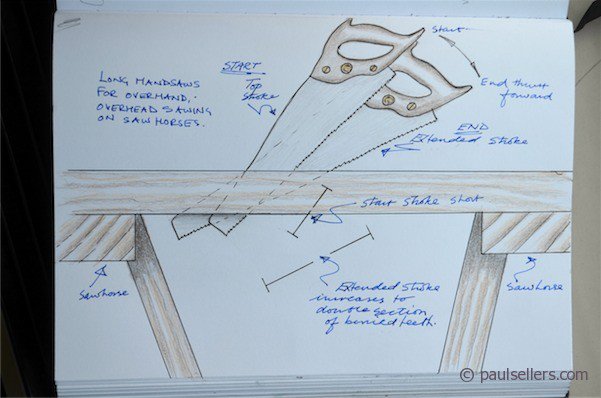

I think that what prompted these thoughts came as a result of my traveling from state to country. In my demo'south I have been working with a 16" Disston handsaw I bought on eBay for £10 ($15 usd). When people see its effectiveness they seem quite amazed. I rip and crosscut with the aforementioned saw too and so they brainstorm request questions. The saw is short and so that makes the saw somewhat unusual, only I similar its shortness for a couple of reasons. Ane, information technology's compact length makes information technology ideal for traveling with and, two, information technology'southward shortened punchiness gives the most inline directness that penetrates right at the heel of the saw. Every bit an at-the-bench saw, where wood is anchored differently than say on saw horses, the presentation of the saw to the wood is more than perpendicular and then has a directness other saws might not have.  On sawhorses the saw is presented at an angle as with most overhand overhead cutting.

On sawhorses the saw is presented at an angle as with most overhand overhead cutting.  That beingness the example, a short handsaw works well for vise work, whereas sawhorse cutting actually relies on the extra length, which gives proficient purchase over the fabric and extra length for those teeth lost in the longer cut with angled presentation of the saw to the woods considering of the angle of the saw engaging within the actual cutting in the wood being sawn. Short handsaws like mine are platonic for larger tenon work because when taper footing, the saw plate (bract) affords greater localized rigidity in forepart of and around the handle expanse of the saw and so a rigid back to the saw is not necessary. This and then allows unlimited depth of cut to the saw.

That beingness the example, a short handsaw works well for vise work, whereas sawhorse cutting actually relies on the extra length, which gives proficient purchase over the fabric and extra length for those teeth lost in the longer cut with angled presentation of the saw to the woods considering of the angle of the saw engaging within the actual cutting in the wood being sawn. Short handsaws like mine are platonic for larger tenon work because when taper footing, the saw plate (bract) affords greater localized rigidity in forepart of and around the handle expanse of the saw and so a rigid back to the saw is not necessary. This and then allows unlimited depth of cut to the saw.

Many of the modern saws used in woodworking today are really well designed for certain spheres of woodworking and I utilise them quite often because of that. The saw in the photo above seems somewhat out of place in my tool chest and generally speaking, for me, it might be. In construction carpentry even so it'south different and specially so in today's carpentry. Most carpenters rely on powered skill saws of i kind or another. These machines crave accessibility to the wood and freedom of movement say across saw horses or the similar. Sheet goods such every bit OSB, MDF, plywood and two-past stock is indeed mostly crosscut cutting (MDF excluded as it has no grain per se). That being the example, there are occasions throughout any day when the skill saw doesn't reach and that'south when a handsaw with induction hardened teeth comes into its ain. These saws will indeed crosscut dimensional lumber very finer and also deal with pressed fibre board (chipboard UK) faced with plastic laminate, melamine and so on. Resins used as binding agents to create engineered boards similar this are extremely hard on all saws as well and so tungsten carbide teeth and consecration difficult-signal teeth get essential.

Many of the modern saws used in woodworking today are really well designed for certain spheres of woodworking and I utilise them quite often because of that. The saw in the photo above seems somewhat out of place in my tool chest and generally speaking, for me, it might be. In construction carpentry even so it'south different and specially so in today's carpentry. Most carpenters rely on powered skill saws of i kind or another. These machines crave accessibility to the wood and freedom of movement say across saw horses or the similar. Sheet goods such every bit OSB, MDF, plywood and two-past stock is indeed mostly crosscut cutting (MDF excluded as it has no grain per se). That being the example, there are occasions throughout any day when the skill saw doesn't reach and that'south when a handsaw with induction hardened teeth comes into its ain. These saws will indeed crosscut dimensional lumber very finer and also deal with pressed fibre board (chipboard UK) faced with plastic laminate, melamine and so on. Resins used as binding agents to create engineered boards similar this are extremely hard on all saws as well and so tungsten carbide teeth and consecration difficult-signal teeth get essential.

Source: https://paulsellers.com/2013/03/handsaw-defined-by-cultural-changes/

Posted by: josephouldives.blogspot.com

0 Response to "What To Draw On A Handsaw"

Post a Comment